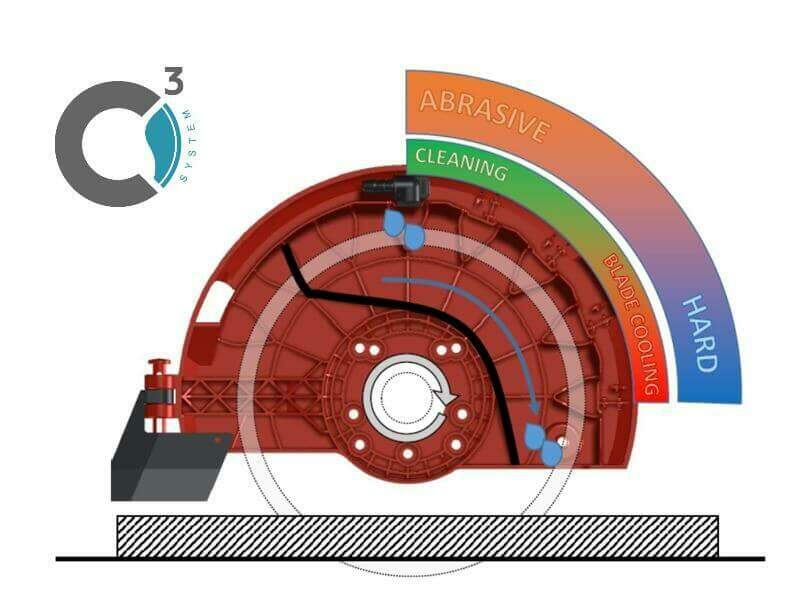

The C3 System has been designed and patented by RUBI, only for DU-EVO and DV electric cutters. Thanks to the C3 System, the user can select the water diffuser’s position depending the material being cut, getting more efficient blade cooling and cleaning, and so, a better blade care.

The names of these 3 concepts have been used to call this singular system: Care, Clean and Cool.

To better understand the operation and benefits of the C3 System, we must, first of all, remember the two main functions of the water in the diamond blade cut.

Even though we always talk about the need to use water to cool the blade during cutting, this is not the only function. The water is also necessary to clean the remains of cut material that may remain adhered to the diamond band. A dirty blade does not cut properly. Additionally, the cutting of ceramic materials with water prevents the generation of dust, and therefore, reduces considerably the user’s exposure to the inhalation of silica dust.

The C3 System allows us to change the water diffuser’s position (within 5 already predefined) and to choose a higher cleaning (highest position) or a better cooling (lowest position)

In addition to increase the efficiency of the cleaning and cooling of the blade, the C3 System, also reduces the loss of water, so, we optimize the consumption of this resource.

Thanks to the new C3 System, we can increase the performance of our electric cutter when facing the big variety of materials currently available.

As classifying them all is not easy, we will summarize it in two: abrasive materials and hard materials.

The materials of an abrasive nature, usually present a high friability* so it is easier that the diamond band of the blade gets dirty.

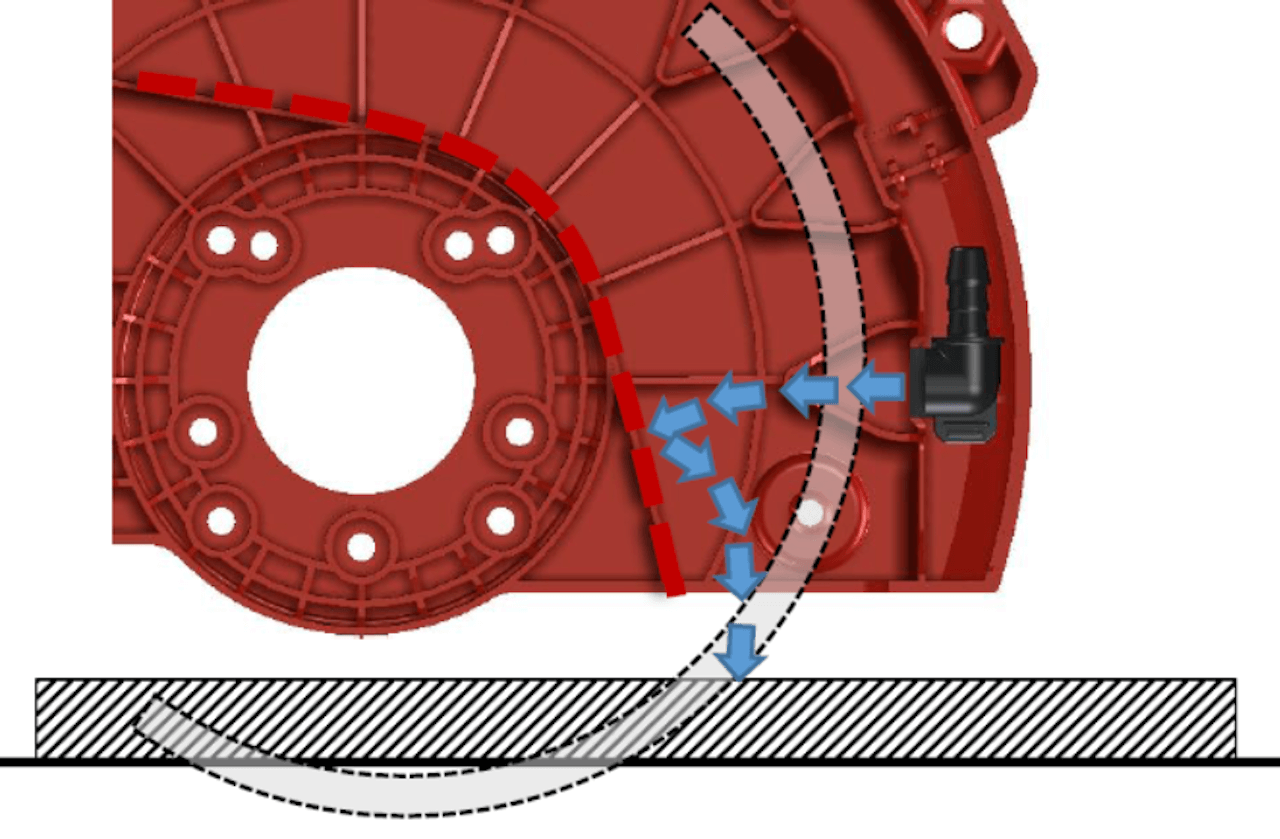

For these cases the C3 System allows to find a higher position of the diffuser. At higher heights, water retention is greater in the inner compartments of the blade protector which, in addition to the speed of rotation of the blade itself, allows us to obtain a more efficient blade cleaning.

CUTTING HARD MATERIALS

During the cutting of hard materials, the friction of the blade increases the temperature.

In these cases, the increase of the cooling is essential.

Selecting a lower position for the diffuser allows the C3 System to retain a smaller amount of water in the internal compartments. The projection of the water bounces in the internal decanter, allowing the water to concentrate by gravity in the cutting area and ensure cooling of the cut.

The result of the combination of all the functions of the C3 System, is a better blade care, and consequently, a higher performance of this consumable.

Keeping the blade in the best condition, not only improves the quality of the cut, it also helps increase the electric cutter performance.

As we have said at the beginning, the C3 System is exclusive for the cutters of the DU-EVO and DV ranges of RUBI. In both ranges, the C3 System is a great advantage, but in the specific case of the DU-EVO and its 1.1 HP engine, this advantage is much greater.

Post a comment