Which are the tips and tricks to get the maximum quality and durability of your RUBI manual cutters?

One of the aspects that the ceramic tile fixer has very clear, is that the acquisition of a manual RUBI cutter is a safe investment.

Not only for the quality and profitability of the tool, but also for its durability.

The average life of our professional cutters is about 10 years.

In today’s post we are going to share some tricks and tips so that your lovely work ‘colleagues’ could give you the maximum quality and durability for years to come.

CLEANING AND LUBRICATION

One of the main advantages of the RUBI manual cutters is that they do not need any type of lubrication.

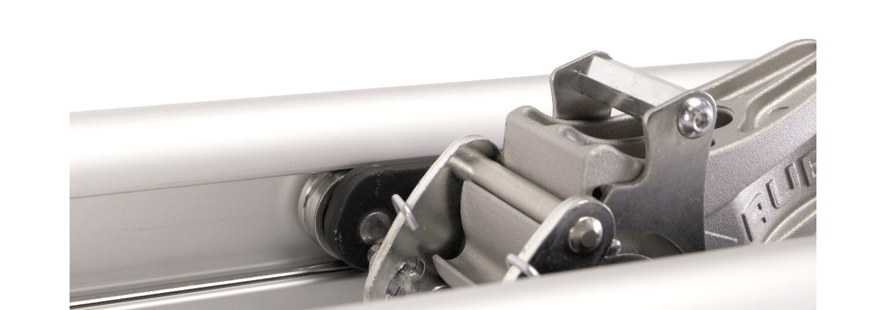

Our models with bushes (TS, TR, TX) and the models with bearings (TZ), do not require any lubrication. So we should never use grease to “improve” its sliding through the guides. That is, in general, one of the biggest mistakes that users make.

During the use of manual cutters, both by exposure to the work environment, as well as by the waste generated by the ceramic itself, when cutting, they are filled with dust and enamel remains. This residue is very abrasive and covers the entire surface of the tool.

In the area of the slides and guides this dust slows the sliding of these parts, forcing its use and, in many cases preventing proper operation.

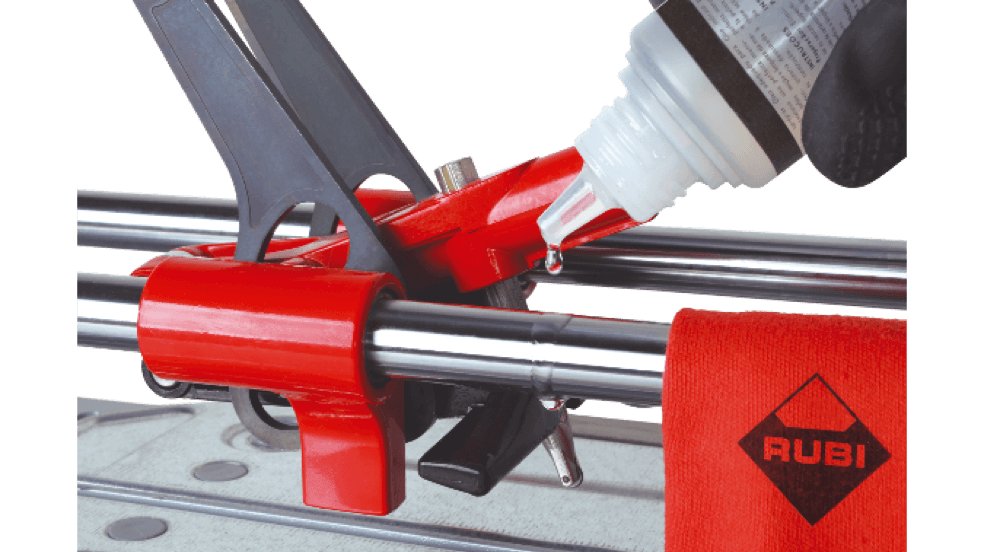

To avoid this, the best solution is to apply a couple of drops of the maintenance kit, directly on the guides, allowing it to enter the gap between the bushings or, in the case of the TZ, on the raceways of the bearings.

Making several passes with the slides throughout the length of the guides, we will eliminate all the residue that may have been inside.

But this is not the most important part. The RUBI maintenance kit includes a cotton cloth. Its function is almost more important than the oil itself.

Never, under any circumstances, you should leave traces of oil, or any other lubricant, on the guides. The reason is simple. The residue that we have mentioned before will adhere to these remains, generating a much greater obstacle than the original one. Meaning, the remedy will be worse than the disease.

That’s what the cotton cloth is for. After applying the oil and distributing it throughout the guide, we must clean and dry them completely of any remaining lubricant.

The guides must be completely clean and dry to the touch. If they stain, they are not very clean.

By performing this operation, at least once a week, the life and operation of our RUBI cutter is assured.

Is it essential to use the RUBI maintenance kit?

Well, the truth is that no. Although the oil in the kit is specially formulated for our cutters, any low-density lubrication oil can be used. Oils used for sewing machines, are the closest thing that the user can find.

What must be clear, is that you do not have to use grease or Vaseline and if you can avoid, any lubricant spray (i.e. WD40).

TRANSPORT

The other fundamental aspect to prolong the life of our RUBI cutter is to take into account how it is going to be transported.

All our professional manual cutters have a practical transport case. Either a rigid version or non rigid version (plastic) or “soft” (textile).

The main function of the RUBI cases is to protect and facilitate the handling and transport of the tool and its accessories.

For this, the RUBI transport cases have several spaces or compartments, specially designed to place the accessories of the cutters.

In this case, we refer especially to the scoring wheels.

Never keep the cutter with the wheel mounted in the tool holder!

Mount the scoring wheel only when you are going to use it. If you have finished your journey or you are not going to use the cutter for a while. Keep the scoring wheel in the transport case.

To summarise…

In this way, we will avoid, in the first place, that the wheel can be damaged if it receives blows during transport or the machine itself or the transport case suffers damage due to the wheel.

Regarding the scoring wheels, remember that the oil in the maintenance kit, you can also use on our scoring wheels. The residue of which we have spoken previously, also adheres to the scoring wheel, so that a good cleaning, not only will allow us to obtain an excellent cut, but we will lengthen the life of our scoring wheel.

Of course, another important aspect is to prevent all these accessories from being lost. If we get used to always keeping them in place, we will always have them at our disposal.

These are just some of the most important tips and tricks to keep our manual cutter in perfect condition.

And you? Do you have a special trick? If so, share it with us on this blog or on our social media feeds.

Post a comment