Tile floors are once again very popular due to the advantages that ceramic tile provides over other flooring materials. But, how many times have you seen issues with tile layouts? Tile installation problems are very common and even experienced tilers may run into issues when dealing with challenging installation projects.

Tile professionals are always looking for the best layout possible or for those little things that will make their installation perfect. So, in this article, we will cover the worst tile installation problems related to floor layout, proper use of materials, tools, and bonding.

Are You Using Tech Gadgets to Layout the Floor?

To understand how the shape affects the installation process, normally a tile setter completes a layout analysis before getting started. However, many tile installation problems come from inaccurate floor layout. Knowing your tile and room dimensions is the first step to completing a flawless project.

The best thing you can do is to start using tile layout software. It will help you measure and complete the layout, but be sure to use a laser measurement tool to get the right room dimensions.

[Looking for the best tile layout software? Watch how the RUBI EASYTILER app can do much more than that (only available for tablets)]

The Most Common Tile Installation Problems

We all have heard that tile installation is relatively easy and can be completed without issues, unless something throws you off. This could be something simple like irregular shapes, subfloors, existing surfaces, or material issues. It is very common to see the same tile installation problems over and over again. Here is a list of the worst tile installation issues and how to avoid them.

1. Loose Tile

Sometimes the existing tiling is coming loose from the substrate and you will not notice it without some investigation. To determine whether the existing tile is in good condition and can accept another tile on top of it, use a tool to gently hit the tile. A hollow sound indicates that the tile is not adhered properly. If this is the case, then the whole floor should sound hollow because of the uniformity of the substrate. Before starting the installation, check the floor and, if needed, remove the loose tiles.

2. Cracked Tile

Sometimes tile will crack without you noticing. Professionals tend to think that the tile cracked because something fell on top of it, but this is not always the case. Cracked tiles may occur because the joists tend to move and tiles may be located mid-span between joists. Before starting the work, make sure that the floor is leveled and the subfloor is properly reinforced. The maximum deflection allowed needs to be in the range of 1/360th of the span length.

3. Not Enough Expansion and Contraction

Curing concrete and the chemical reaction process are two critical items affecting the expansion and contraction of tiles. The lack of proper joints, especially against adjacent surfaces or materials, can cause tiles to pop into the air. The tiles will expand and contract, so be sure to leave at least ½ inch in between the last line of tiles and the next surface or material (on the floor or wall) to allow for both materials to expand and contract accordingly. Remember, smaller joints are susceptible to fail if not done adequately.

4. Lack of Cleaning and Poor Workmanship

This is very clear, right? Well, sometimes tile setters will not take proper precautions cleaning the tiles and preparing the surface. Properly cleaning the back of tile will help obtain better bonding between the adhesive and the surface. Using the right joint and caulk is a best practice that will facilitate the installation work. It is important to highlight that proper inspections should take place at least 6 feet away from the tile, anything closer than that does not follow ANSI standards and might create additional issues.

5. Improper Adhesive

Sometimes, the amount of adhesive is not enough or there is adhesive only on the corners and the center of the tile. The adhesive must be spread uniformly underneath the tile, creating an even layer. On residential installations, the tile must adhere at least on 80% of the contact surface, while commercial tile installations should have 95% of adhesive on the contact surface.

What happens when the adhesive is too strong? This might sound odd, but sometimes the adhesive creates a better bonding with the substrate than with the tile, causing a weak point at the tile adhesion. To avoid this, follow manufacturer’s recommendation and use the right adhesive for the type of substrate and tile you are working with. The performance and characteristics of the adhesive may change depending on the setter’s methods and materials.

6. Using the Wrong Underlayment

When it comes to installing tile, the rule of thumb is to have at least 1 1/4″ of subfloor sheathing underneath to provide the necessary strength. The underlayment should be placed over a mortar bed. This mortar bed is important but it is not a substitute for the tile adhesive, the main purpose of which is to fill gaps and provide a workable, level surface. Now that the underlayment is in place, the next step is attaching it to the subfloor.

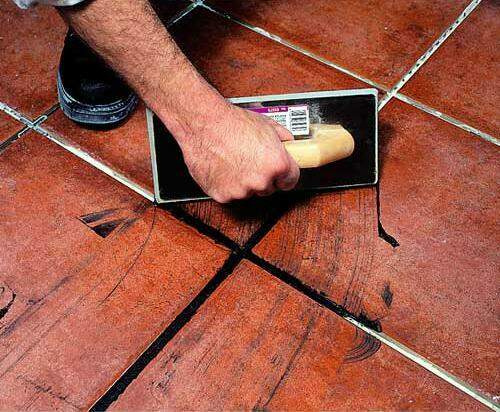

7. Applying the Wrong Grout

Using the right amount of water when mixing grout will prevent it from being too dry and help you get the right consistency during the installation process. A good tile setter is aware of issues with grout coloring and buys the necessary amount of grout all at once, avoiding multiple orders of grout. Grout manufacturers can use different materials causing changes in the grout color. We recommend using sanded grout as it offers more consistency and better results than the non-sanded grout. Two hours after finishing the grouting process, proceed to remove the excess of grout from the tile. Two hours is typically enough time for the grout to dry.

[RELATED: Are you mixing mortar correctly? Read the expert’s guide to mix mortar like a pro]

8. Installing Tile Over Poorly Prepared Subfloor

Many tile installation problems happen because the substrate or subflooring is not ready or lacks the proper preparation. If you have no other option than installing tile over another type of material, make sure you verify the following:

- Check the existing tile and make sure there are no loose or chipped tiles that can prevent proper adhesion.

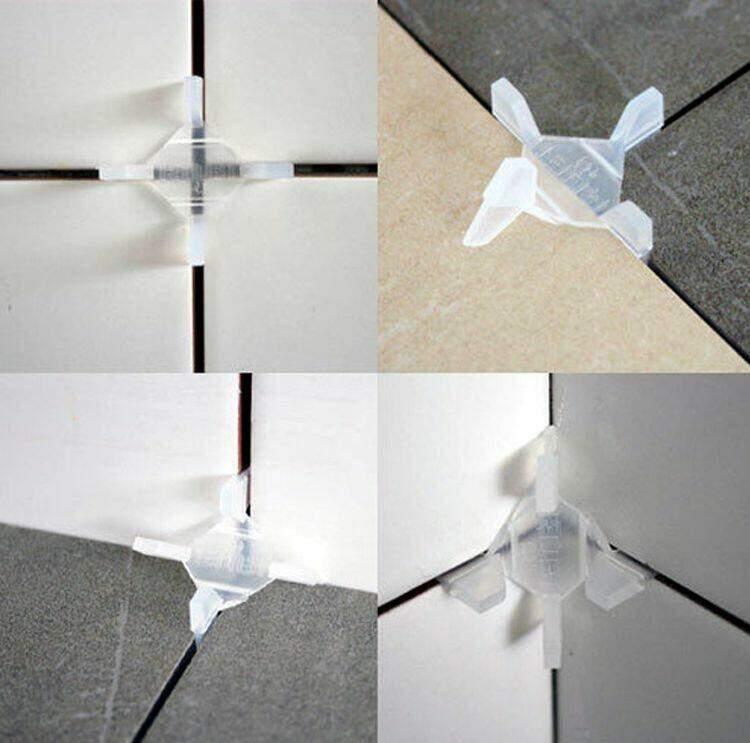

- It is extremely important to level the surfaces. You can level the surface using a grinder, sander, or a tile level system.

- Create a rough surface to improve bonding. The existing surface needs to have some sort of roughness that will facilitate the bonding between the new adhesive and the old surface.

- Use a vacuum to remove all dust, clean with water, and remove all dust particles and debris from the surface.

- Use epoxy or another adhesive material recommended for this type of installation and surface. This can help you avoid common tile installation problems later.

Now that you have verified these issues, check the following points:

- Tile Over Wood Subfloor – Make sure there is no moisture or water affecting the wood and apply thin-set adhesive and install backer board. Use leveling compound to level the surface to minimize cracks in tiles over time.

- Tile Over Existing Tile Floor – Be sure to break or create a rough surface so the adhesive can properly bond both surfaces. If possible, remove the tiles or at least be sure to create a rough surface.

- Tile Over Hardwood Flooring – This is not the best option. It’s actually a mistake. If possible, don’t do it. If you don’t have another option, remove the polyurethane membrane of the hardwood flooring to create a better bonding surface. Before starting, verify the condition and spacing of the joists as it might change from older to newer constructions. Also use a modified thin-set type of mortar for better results

- Tile Over Vinyl Floor – In situations in which a vinyl floor has been installed over concrete, take extra time to make sure the vinyl is clean and ready to receive the thin set mortar.

Did we forget to mention other frequent tile installation problems? Let us know in the comments below!

Awesome article with great information provided by your article, here I would like to thank you guys for sharing such a fantastic blog. Regards Tiles cleaning and sealing in dubai</a

Awesome article with great information provided by your article, here I would like to thank you guys for sharing such a fantastic blog. Regards Tiles cleaning and sealing in dubai

Thank you!

Awesome article with great information provided by your article, here I would like to thank you guys for sharing such a fantastic blog. Regards Wooden floor polishing dubai

Your article provides such a great information with good knowledge. Here we would like to inform you as we are professional cleaning & painting service providers in Dubai! Regards Tiles grout cleaning dubai

Wonderful information, thanks a lot for sharing kind of information. Your website gives the best and the most interesting information. Thanks a ton once again, Regards, Tiles grout cleaning dubai

Your blog is informative, it gave more information for us who are in the tiling services.

I’d say to avoid all these mistakes, it is very important for homeowners to choose a tile installer that has passion and great workanship. The type of materials and tile laying techniques used will all follow if you have someone who has strong attention to detail working for you.

Thank you for sharing your blog, seems to be useful information can’t wait to dig deep!

Fantastic Blog! This is the type of post that needs to be given and not the accidental misinformation that’s at the other blogs. Appreciate your sharing. Kindregards, Marble floor restoration Dubai

Wonderful information, thanks a lot for sharing kind of information. Your website gives the best and the most interesting information. Thanks a ton once again, Regards, Marble polish company Dubai

lovely information as we have been looking for… Your article is fantastic and I would like tell you that you have done great job and we looking forward to read more. Keep up the good work. RegardsMarble cleaning services company in Dubai

Awesome article with great information provided by your article, here I would like to thank you guys for sharing such a fantastic blog. Regards Wooden floor polishing dubai

Thanks for sharing this detailed post. Very Informative. Will be waiting for your next blog^ ^

Thank YOU for reading!

I have put on kitchen wall tiles black and cream alternatively. We are using a black glitter grout. These tiles are porous. Every time we try to clean the grout from the tiles it’s leaving awful black glitter grout marks all over the tiles especially visible over the cream. We have tried so many cleaning products but nothing seems to work. Please is there a remedy for this we would be most grateful as we are at our wits end. Thanks any help appreciated.

It sounds like the grout it already in the pores of your tiles, which will be very difficult to fix. If I were you I would replace the affected tiles. However, you should definitely SEAL your tiles first. We have an article on our blog on just how to do that called “5 Tile Sealer Best Practices.”

How do I avoid tiles falling off after a few years?

My floors and table tops were covered with tile, one by one the tiles are falling off, especially the vertically placed tiles, placed just off the tables surface. I should post a photo.

If I could go back and use a better tile layer, I would! How do I know these men know what they are doing? I need to do the entire job over.

Hello Tracy. We are sorry to hear that your tile installation isn’t lasting. Here’s a short tiktok video from our channel that shows proper tile and adhesive laying technique. If they are laying the adhesive and the tile the way it’s shown in this video, then the installation should last at least 10 years, probably more. Check it out so that while you look for an installer, you can ask about his technique and know if it’s good or not.

Fantastic blog guys! Very happy to read your blog as it has many ideas with lots of knowledge which can be used. Look forward for more and more blog of yours. You guys are amazing. Warm regardsMarble floor restoration Dubai

Awesome article with great information provided by your article, here I would like to thank you guys for sharing such a fantastic blog. Regards Wooden floor polishing dubai

Awesome article with great information provided by your article, here I would like to thank you guys for sharing such a fantastic blog…. Regards Wooden floor polishing dubai

How about the floor is walked on in just 12 hours everyone should first and last read the instructions before starting. How to mix, how long before they can do other work on the tile that was laid late the night before!