Ceramic tiles are thin pieces made of clay, silica, dyes and other raw materials to make floors and wall tiles. The best-known types of ceramic tiles are stoneware tiles or porcelain stoneware. To know how to tile and install ceramic tiles correctly, we must know the material we are dealing with.

There are different placements, tools and adhesives to use when it comes to ceramic tiles. Because of this we have dedicated this post to talking about the basic concepts and characteristics of this material.

WHAT ARE CERAMIC TILES?

Ceramic tiles are generally thin (although currently up to 20 mm can be found) made of clay, silica, dyes, and other raw materials. These individual ingredients are ground, pressed or compacted using different procedures. They then undergo a process (or several) of heating and cooling. These raw materials, procedures and manufacturing processes create different products with different characteristics, although the most common is still “fired clay”.

Some of the best-known types of ceramic tiles are stoneware tiles or porcelain stoneware. The main difference between these types is their porosity (water absorption through the tile) and their hardness. According to these characteristics, each of these types of ceramic tiles will be used for floors both indoors and outdoors, or as wall and façade coverings.

CERAMIC TILES TYPES:

The different types of ceramic tile that exist are classified in many ways:

- For its finish; glazed (GL) or unglazed (UGL).

- By its location; exterior or interior, flooring or cladding.

- By manufacturing process: pressing or extrusion.

- By water absorption capacity: High, medium or low.

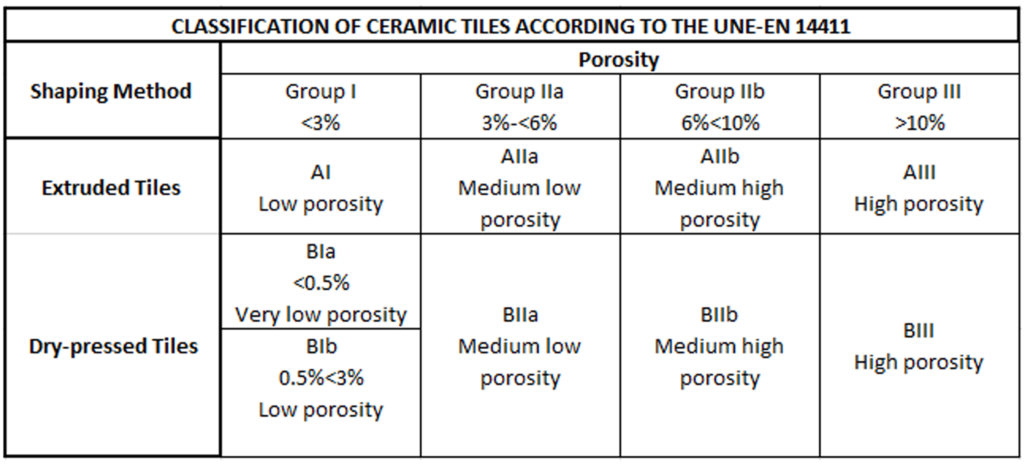

The UNE-14411 Standard obliges manufacturers to indicate this type of information on the packaging of their products . So we can know the type of material we have in our hands just by reading the tile box.

This encoding is summarized in the following table :

As a starting point, we will start with the two most typical and traditional materials:

TILES

The porosity of the tiles is the highest, but remember that is only through the back of the tile, never through the front enamel. The back is porous and can be white, grey or red. Absorption is between 12% and 20%, although in some cases it can reach 25%. That is why we will always see the tiles within Group III.

They are mainly used for interior wall cladding.

It is obtained using the semi-dry pressing technique and with one or more firings (single firing or double firing). The surface is enamelled, with a wide range of colours and decorations.

The hardness of the tiles will also depend on the enamel, but it is usually less than 5 on the Mohs scale, with a breaking load between 300 and 1200 N. This means that we do not need a great separation power to cut this material.

Any PRO RUBI manual cutter with a Ø 6 or 8 mm scoring wheel will be perfect for cutting these tiles. Some examples are the STAR , FAST and SPEED-N ranges .

STONEWARE TILES

Ceramic stoneware tiles are basically used for floors and can be laid both indoors and outdoors. They are commonly formed by the semi-dry pressing method, although there are some cases of extrusion. All of them are subjected to a single firing.

We can find stoneware tile models with a white back, known as white-paste stoneware, and models with a red back (the most common). Also, stoneware with glazes with various levels of roughness, which will add more difficulty to the cut.

The hardness of stoneware tiles is usually between 3 and 8 according to the Mohs hardness scale. The smoother the texture of the tile surface, the lower its hardness.

When it comes to the absorption capacity, it is between 2% and 10% depending on whether the back is more or less vitrified. For this reason these ceramic tiles are usually in Group II.

Its breaking load oscillates between 1000 and 2300 N, but if we increase the thickness, we may need separation powers close to 500 Kg.

To cut the stoneware we can use a RUBI PRO manual cutter and in some more complicated cases a SUPERPRO, ideally with a Ø 10 mm scoring wheel. Some examples would be the TS-MAX , TQ or TR-MAGNET ranges . We can have many formats of stoneware tiles. Currently, 20×20, 30×30 and 40×40are popular, but the trend is increasing to 50×50 and 60×60 formats.

PORCELAIN STONEWARE TILES

Porcelain tiles have so many applications due to their impressive features. They can be used both indoors and outdoors for floors and walls. Porcelain can also be used as countertops, furniture coverings and even ceiling tiles.

The current popular small formats include 30×30 or 40×40, through large formats such as 60×20 up to 120×40. Although larger formats are available such as 260×120, 300×100, up to a maximum of 360×160.

The conformation of these large formats is usually done following new methods such as continuous sheet roller pressing.

The thicknesses can range from 3 mm to 20 mm. Their absorption is minimal, always being below 0.5 and for this reason we will always find these ceramic tiles in Group I.

Its minimum porosity translates into great hardness and resistance to cutting.

Its breaking load can reach up to 10,000 N, which is why it is not recommended to use cutters with a separation power of less than 800 kg to cut porcelain on a regular basis. Any PREMIUM RUBI manual cutter and many SUPERPRO ones will serve us perfectly for this task. And the Ø 8 mm ENDURE scoring wheel or a Ø 22 mm EXTREME scoring wheel will make the perfect team. Within the PREMIUM catagory we have the TX-MAX and TZ ranges.

Now you know in more detail the three most popular types of ceramic tiles, and the recommended tools for cutting each of them.

If you want to know more, we recommend you take a look at our other posts on our blog related to the subject.

Post a comment